PRECISE KIMLA STREAMCUT 4121 WATER CUTTING

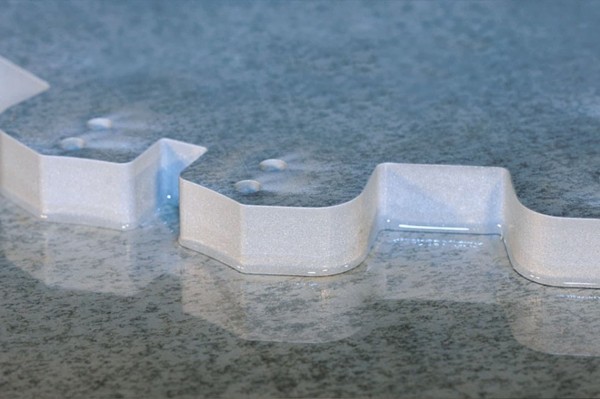

Waterjet is one of the most appreciated cutting methods currently used in various industries. This technology is an ecologically clean process.

- allows you to cut any shape

- the waterjet technique can be used in almost any material up to 200 mm thick

- working field: 2,050 x 4,050 mm

- the waterjet cutting method is characterised by low cutting temperature

- cutting with water leaves smooth, matte edges

- the material does not deform and does not change its properties

- water-cutting ensures repeatability of cutted elements

In the method using water-cutting, no toxic dust or gases are emitted and the amount of waste is minimised. The residues that arise during operation – used abrasive and particles of cutted material – are collected at the bottom of the water tank and are treated like debris - reprocessed. The amount of water used is small and the materials do not require additional treatment what reduces production costs.

-

SMALL FORCES AFFECTING MATERIAL

SMALL FORCES AFFECTING MATERIAL

-

LOW CUTTING TEMPERATURE

LOW CUTTING TEMPERATURE

KIMLA STREAMCUT 4121

The water-cutting machine (i.e. the CNC Waterjet KIMLA STREAMCUT 4121), is equipped with a high-pressure pump with a pressure booster and accessories from the renowned American company Accustream. This design ensures a high quality of cutting thanks to the generation of sufficiently high-pressure waterjets and precise machining without great effort.

Laser-Cutting

Laser-Cutting Water-cutting

Water-cutting Sheet

Sheet Welding

Welding Railings

Railings Blasting

Blasting Pulverulent

Pulverulent Advertisement

Advertisement Storage

Storage